Methodology

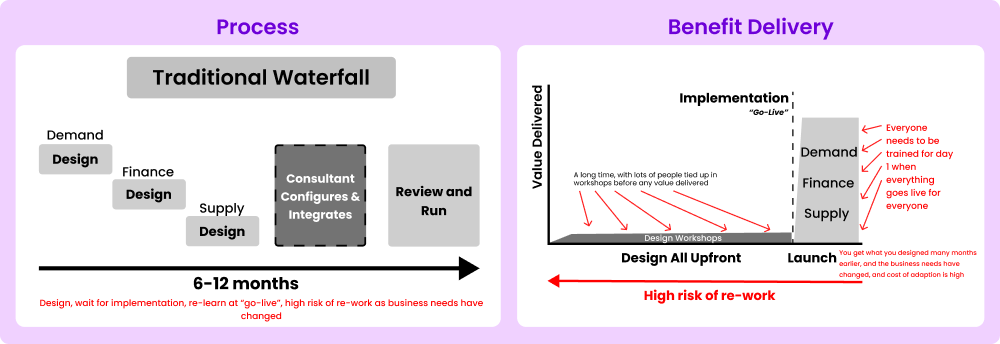

Traditional waterfall methodology is still deeply embedded in many supply chain planning programs. It appears structured, predictable, and “safe” from a governance perspective. In reality, it is fundamentally misaligned with how supply chains operate today – dynamic, volatile, and constantly changing.

The core issue is simple: waterfall is built to optimize design completion, not business outcomes.

How the Traditional Waterfall Process Works

The classic setup follows a linear sequence:

- Demand design

- Finance design

- Supply design

- Consultant configuration & integration

- Review and run

This entire cycle usually takes six to twelve months. During that time, the organization is largely waiting. Workshops consume planners’ time, but the system itself delivers no operational value. Decisions are still made outside the tool, often in spreadsheets, while the future-state solution exists only in slide decks.

The Illusion of Control

Waterfall gives stakeholders a sense of control because everything is defined upfront. In reality, this control is fragile. Assumptions made early in the project quickly become outdated as demand patterns shift, portfolios change, or constraints emerge. The longer the design phase, the higher the probability that the final solution no longer reflects how the business actually works.

By the time configuration starts, the design is already aging.

The Go-Live Shock

When the system finally goes live, everything happens at once. Demand, finance, and supply processes are launched simultaneously. Users are expected to learn new tools, new logic, and new ways of working under real operational pressure.

There is no gradual adoption curve. Training is compressed, mistakes are inevitable, and confidence in the system drops quickly. Instead of supporting planners, the tool often becomes something they work around rather than with.

Re-Work Becomes Inevitable

Because all design decisions were locked early, any mismatch discovered at go-live is expensive to fix. Changes ripple across the entire setup. What could have been a small adjustment months earlier now requires reconfiguration, retesting, and renewed alignment across teams.

This is where many programs stall, lose momentum, or quietly accept suboptimal processes just to avoid reopening the design.

Value Comes Too Late

Perhaps the biggest flaw of waterfall is that value is delivered only at the end. For months, the benefit curve is flat. There are no early wins, no feedback loops, and no proof that the approach is working. Leadership invests significant time and budget before seeing any tangible return.

In fast-moving supply chain environments, delayed value is often equivalent to lost value.

The Real Problem

Waterfall assumes stability – stable requirements, stable data, stable organizations. Supply chains are none of these. They evolve constantly, and planning systems must evolve with them.

A methodology that postpones value, ignores learning-by-doing, and treats adoption as an afterthought is structurally flawed.

Closing Thought

Traditional waterfall planning is not failing because teams execute it poorly. It fails because it is designed for a world that no longer exists.

Modern supply chain planning requires adaptability, early feedback, and continuous value delivery. Anything else is a risk, no matter how well documented it is.

Read how IBP Ready replaces long waterfall programs with a focused, 14-day SAP IBP activation that delivers value early and evolves with the business:

👉 https://ibpready.com/sap-ibp-in-14-days