Supply Chain Visibility: From Blind Spots to Control

Supply chain visibility is no longer a nice-to-have. It is a basic requirement for planning that actually works.

Most planning problems don’t start with bad forecasts or poor execution. They start with not seeing the full picture. When planners lack visibility across demand, supply, inventory, and components, decisions are made late, risks surface too late, and costs spiral before anyone can react.

Visibility is the difference between reacting to problems and preventing them.

Why Lack of Visibility Breaks Planning

In complex supply chains, decisions are interconnected. A constraint in one location, supplier, or component quickly cascades across the network. Without visibility, these dependencies remain hidden until they show up as shortages, delays, or missed customer commitments.

Typical symptoms of poor visibility include:

– Bottlenecks discovered only after orders are late

– Components failing without knowing where else they are used

– Planning done in silos instead of across the network

– Firefighting instead of controlled decision-making

When planners only see fragments of the network, the supply chain becomes reactive by design.

What True Supply Chain Visibility Delivers

Visibility is not about dashboards for the sake of reporting. It is about enabling better decisions earlier.

When visibility is in place, planning teams can:

– Spot risks before they escalate into shortages or delays

– Understand how issues propagate across products and locations

– Act faster using real, connected data

– Reduce unnecessary buffers, expediting, and last-minute buying

This directly impacts cost, service levels, and customer reliability.

Visibility as the Foundation of Modern Planning

A visible supply chain is a connected one. Demand signals flow into supply and inventory decisions. Constraints are seen across levels, not hidden inside spreadsheets or isolated planning views.

This connection allows planners to move from:

– Static plans to dynamic scenarios

– Reactive firefighting to proactive control

– Local optimization to network-wide decisions

Without this foundation, even the most advanced planning logic struggles to deliver value.

Supply Chain Visibility in SAP IBP with Supply Chain Explorer

SAP IBP provides a strong planning backbone, but true network visibility requires more than standard views. Planning teams need to clearly see dependencies, constraints, and impacts across the entire network.

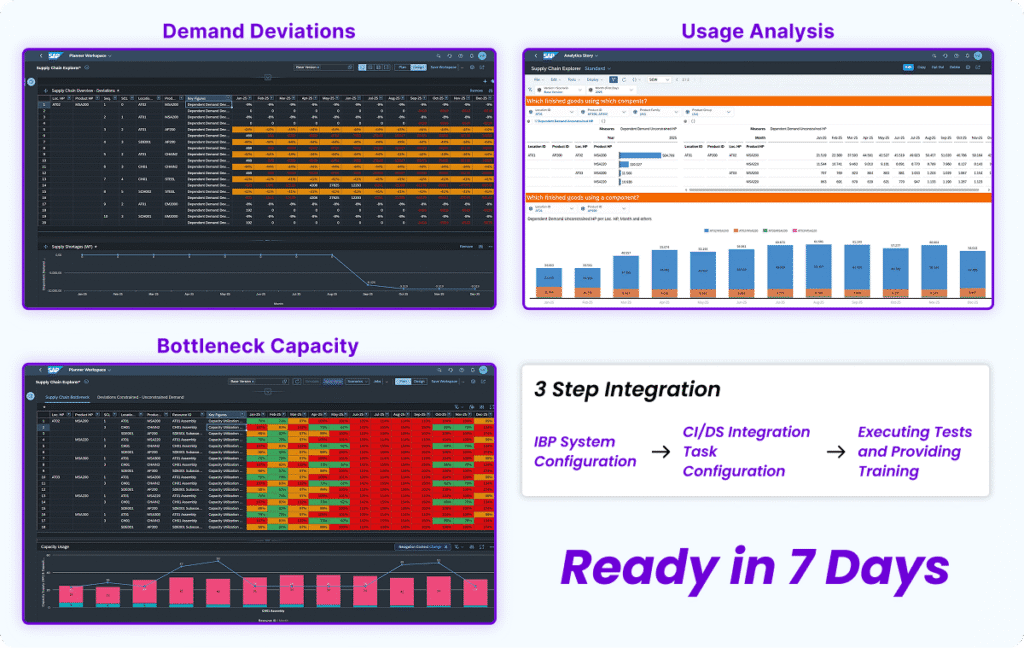

Supply Chain Explorer, built directly into SAP IBP by IBP Ready, turns visibility into action. It gives planners one connected view of the supply chain, allowing them to detect bottlenecks early, trace component dependencies, run what-if scenarios, and understand multi-level BOM impacts in real time.

Instead of reacting to disruptions, planners can anticipate issues and act before they affect service or cost.

From Visibility to Control

The outcome of true supply chain visibility is not just better insight. It is better control.

With one view of the entire network, planning teams make faster decisions, reduce risk, and align execution with reality. The supply chain stops reacting to problems and starts anticipating them.

Supply Chain Visibility in SAP IBP with Supply Chain Explorer

SAP IBP provides a strong planning backbone, but true network visibility requires more than standard views. Planning teams need to clearly see dependencies, constraints, and impacts across the entire network.

Supply Chain Explorer, built directly into SAP IBP by IBP Ready, turns visibility into action. It gives planners one connected view of the supply chain, allowing them to detect bottlenecks early, trace component dependencies, run what-if scenarios, and understand multi-level BOM impacts in real time.

Instead of reacting to disruptions, planners can anticipate issues and act before they affect service or cost.

👉 Read more about supply chain explorer here: https://supplychain-explorer.com/sce

Final Thought

Supply chain visibility is not a reporting exercise. It is the foundation of effective planning.

Without visibility, planning will always lag behind reality. With it, organizations gain the clarity needed to make confident decisions and keep the entire network under control.

For companies running SAP IBP, the question is no longer if visibility is needed, but how fast it can be achieved.