After seeing how many supply teams struggle with plans that look perfect in Excel but fall apart in execution, we created the Supply in 14 Days Sprint to close the gap between plan and reality. Instead of long design phases and static simulations, this sprint builds a live, constraint-aware model that shows where your network really breaks – and how to fix it. It’s a fast, practical way to turn disconnected data into a feasible, transparent plan that your team can trust and act on within two weeks.

SAP IBP Supply in 14 days

INSPIRATION

Plans that aren’t feasible

Supply plans often look good on paper but collapse under real constraints like limited capacity, missing materials, or lead-time shifts. Teams spend days firefighting instead of executing.

No visibility into constraints

Capacity, materials, and supplier limits live in separate files or systems. Planners can’t see bottlenecks until orders start failing.

Slow scenario response

Testing alternate suppliers or shifting production takes days, sometimes weeks. By the time one scenario is ready, the situation has already changed.

Siloed functions and priorities

Production, procurement, and distribution optimize locally instead of together. The global plan never truly balances demand, capacity, and cost.

HOW WE DO IT

14 Days

1. Sprint 0 prep

- Stakeholder mobilization

- Initial Workshop

- Master Data Preparation

- Key Initial Needs

2. Network & data

- Product Data

- Capacity

- Routings

- Inventory

- Transport link

- Supplier Sources

3. Planning logic

- Heuristics first

- Constraints

- Unconstrained Heuristics

- Lead Times

- Lot Sizes

- Master Data review needs

4. Visibility & exceptions

- Exception cockpit

- Notifications

- Scenario

5. Learn & adapt

- Review

- Fixes

- Stabilize

6. Supply deliverables

- Plan

- Logic

- Visibility

- Simulation

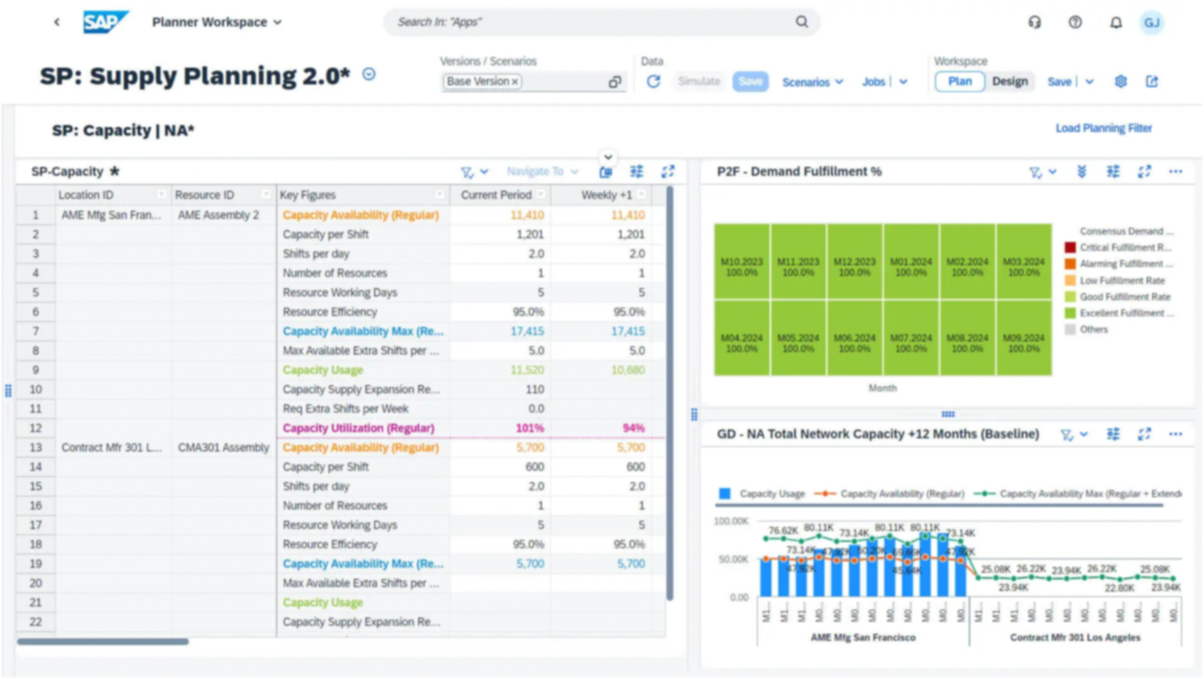

The Supply in 14 Days Sprint is a fast, hands-on way to turn disconnected supply data into aworking, constraint-aware planning model. In just two weeks, we build a live environment thatconnects demand, capacity, and materials – showing where your plan breaks and how to makeit feasible. Through six focused steps, we define scope, load essential master data, modelconstraints, highlight bottlenecks, and create visibility through dashboards and alerts. By the end,you have a transparent supply plan, exception-based plan, capacity and bottleneck dashboards,and a simulation playbook for quick what-if scenarios – giving planners clarity, speed, andcontrol over their network, all within 14 days.

WHAT YOU GET

Reliable Supply Plan

Turn disconnected planning data into a single, constraint-aware plan that connects demand, capacity, and materials. Planners can trace shortages, capacity issues, and adjust the plan based on real bottlenecks – not assumptions.

Key focus areas:

- Reliable supply plan generation

- Demand to supply connected

- Resource Capacity view

- Supply chain network visibility

Visibility & Control Dashboards

Gain clear insight into where the plan breaks and why. Dashboards show utilization, shortages, andlate supplies – all linked to alerts and workflows forfaster action.

- Capacity & bottleneck dashboard

- Shortage heatmap

- Planning by Exceptions

Simulation & Playbook

Test network changes in minutes, not days. Quicklymodel new supplier, warehouse, productioncapacities, delays, lead-time shifts and see theimpact before it happens.

- What-if simulations

- Alternate source testing

- Capacity flex scenarios

FAQ

No. We start with what’s available - usually BOMs, lead times, andcapacity data for key sites. Missing/wrong data is flagged and withlogical assumptions so you can see the model working early and refineas we go.

Both. We configure a live planning model that connects materials, capacity, and demand - but every step is validated with planners to make sure the output makes business sense.

Typically, the Supply Planner or Master Scheduler, someone from Production or Operations, and master data owner. Optional roles are identified with individual case.

A live, constraint-aware supply model - with capacity visibility, andexception dashboards - plus a simulation playbook showing how to run“what-if” scenarios (e.g., supplier delays, capacity shifts, demandspikes).

You can either expand the model to more products or sites, or connect it with Demand and Inventory for a full E2E planning flow. Everything built in the sprint remains usable and production-ready. The aim being to deliver fast, learn along the way and buildonly what’s required after learning what the system can deliver.

Check out some of our case studies

Lucozade Ribena Suntory: Demand Planning

A fragmented forecasting process was replaced with a structured, exception-based approach in SAP APO. Sales collaboration improved, forecast accuracy increased,...

Fragmented to Unified Planning

A focused two-month engagement delivered a streamlined S&OP process, aligning cross-functional teams and creating a phased SAP IBP roadmap. With...

SAP IBP Education Partner

Read how Romain Blaser (IBP Ready’s founder) led 15+ SAP IBP trainings across Europe, turning complex topics into practical lessons...